HOT PRODUCTS

What a Commercial Sparkling Water Dispenser Should Deliver in Daily Service

A commercial sparkling water dispenser is not a “bigger home unit.” In hospitality, offices, gyms, and high-traffic public spaces, performance is measured by three operational outcomes: stable temperature control, consistent carbonation, and fast, intuitive dispensing that prevents queues.

In practice, the most reliable installations align the dispenser’s configuration with your use case: service speed (peak demand), menu/guest preference (sparkling vs. still vs. ambient), and site constraints (counter space, back-bar space, or undercounter cabinetry). For businesses evaluating multiple options, reviewing a dedicated commercial lineup such as our Commercial Series helps you shortlist formats (countertop, undercounter, floorstanding, wall-mounted) before you compare specifications.

Where commercial users typically gain the most value

- Front-of-house speed: fewer staff interruptions, faster self-serve or assisted service.

- Consistent guest experience: stable cold range and carbonation feel, even during peaks.

- Reduced consumables handling: less bottle storage, fewer deliveries, less waste management.

Capacity Planning: Match L/h Output to Peak Demand (Not Daily Average)

For commercial sparkling water dispensers, “capacity” is most actionable when expressed as liters per hour (L/h) under realistic peak usage. A simple sizing approach is to translate peak servings into liters per hour.

A practical sizing method you can use immediately

- Estimate peak servings per hour (not per day). Example: 120 guests/hour at lunch with 40% choosing water = 48 servings/hour.

- Select a serving size (typical glass range is 250–330 ml). Using 300 ml: 48 × 0.3 L = 14.4 L/h.

- Add a safety margin (commonly 2×) for unexpected spikes and simultaneous dispensing. 14.4 L/h becomes ~29 L/h target capacity.

- Choose a model with adequate cooling output and buffering (ice bank/tank volume) so temperature remains stable during bursts.

As reference points, commercial countertop and undercounter systems in our HoReCa range include 60 L/h and 90 L/h cooling capacities, which correspond to roughly 200–360 servings/hour if you assume 250 ml servings (60 ÷ 0.25 = 240 servings; 90 ÷ 0.25 = 360 servings). This is why high-capacity units can comfortably handle busy service windows when paired with appropriate layout and workflow.

| Example model | Format | Water options | Cooling capacity | Ice bank volume | Sparkling tank volume |

|---|---|---|---|---|---|

| BST60A | Countertop | Sparkling + Cold | 60 L/h | 12 L | 1.8 L |

| BST90A | Countertop | Sparkling + Cold + Ambient | 90 L/h | 18 L | 1.8 L |

| BSD90A | Undercounter | Sparkling + Cold + Ambient (variant dependent) | 90 L/h | 18 L | 1.8 L (sparkling variant) |

Most commercial cold systems operate in a controlled range; for example, these configurations specify a cold water temperature of 4–12°C. If your concept requires colder pours (or extreme ambient temperatures), discuss site conditions early so the system is configured appropriately.

Choose the Right Format: Countertop vs Undercounter vs Floorstanding

The correct physical format is often more important than minor specification differences. Layout determines how often guests and staff interact with the unit, how easy sanitation is, and whether the dispenser becomes a service bottleneck.

Countertop dispensers

- Best for visible, guest-facing hydration points (buffets, meeting rooms, cafés) where fast access matters.

- Simplifies installation and service access, especially when you want manual taps or simple button operation.

- Common choice when you want a compact unit with clear, immediate user feedback.

Undercounter dispensers with a dispense tower

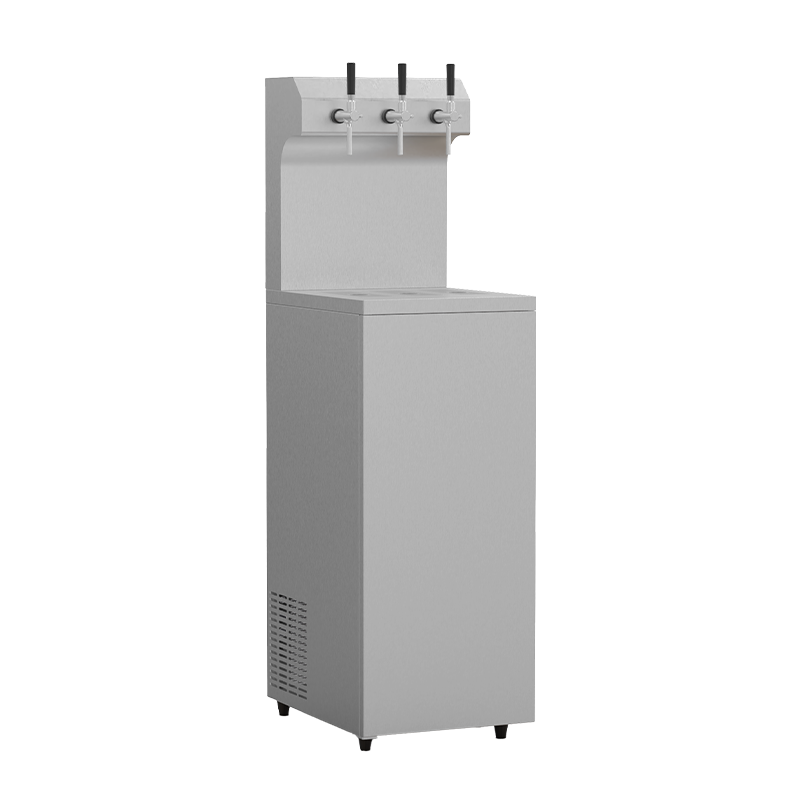

Undercounter designs keep the “engine” out of sight while delivering water through a tower or tap set. They are ideal for premium bar counters, tight spaces, or any concept that prioritizes aesthetics and countertop real estate. A typical application is a gym or hospitality environment using a unit like the BSD90A undercounter configuration, where you want high output without a countertop footprint.

Floorstanding and wall-mounted options

For corridors, public areas, schools, and facilities management projects, floorstanding and wall-mounted layouts can improve accessibility and traffic flow. The key selection factor here is serviceability: filters and sanitation points should remain easy to access without disrupting the surrounding area.

Water Options and Controls: Reduce Queues and Operational Friction

Commercial users generally benefit from offering at least two modes (sparkling + cold) and, in many environments, adding ambient water reduces ice requests and supports faster consumption. Three-option systems (sparkling/cold/ambient) are commonly used in hotels, conference areas, and higher-end hospitality because they fit a broader range of preferences without additional service labor.

Manual taps vs button or touchscreen operation

From a manufacturer’s perspective, the control interface is a workflow decision. Manual taps are intuitive and resilient for many HoReCa applications; push buttons can improve portion consistency and reduce accidental overfill; and many commercial series designs can include touchscreen selection where users choose temperature, volume, and (where applicable) filtration settings. If you anticipate varied users (self-serve offices, shared facilities), an intuitive interface often delivers a measurable reduction in wait time.

A quick checklist for matching options to your venue

- Restaurants/cafés: sparkling + cold, fast service, compact footprint, easy wipe-down surfaces.

- Hotels/meeting rooms: sparkling + cold + ambient for broader guest preference coverage.

- Gyms/wellness: undercounter integration, energy-efficient operation, stable output through peaks.

- Offices: multi-temperature selection, user guidance, and reminders for routine service actions.

Water Quality, Filtration, and Certifications: What Procurement Should Validate

Taste consistency and compliance are often the deciding factors for chain deployments. In a commercial sparkling water dispenser, water quality is influenced by filtration design, sanitation practices, and the ease of maintaining the system over time.

What “multi-stage filtration” typically means in commercial practice

Many commercial series designs use multiple stages—often a combination of pre-filtration, activated carbon, and reverse osmosis (RO) depending on local water conditions and target taste profile. The operational advantage is not only removal performance but repeatability: consistent water quality helps carbonation taste “cleaner” and reduces variability between sites.

Serviceability matters as much as filtration performance

- Fast filter access reduces labor and lowers the risk of missed maintenance windows.

- Filter-change reminders/notifications (where equipped) improve consistency across multi-site operations.

- Certification and documentation should align with your market and channel requirements; for example, commercial product lines may carry internationally recognized certifications such as UL, NSF, CE, and CB depending on model and destination requirements.

If you are specifying for multiple regions, standardize early on electrical requirements, certification targets, and consumable parts strategy. This reduces lead-time risk and makes field maintenance more predictable.

Carbonation System Considerations: CO₂ Management, Safety, and Consistency

Carbonation consistency is determined by stable cold temperature, controlled CO₂ dosing, and appropriate buffering. In commercial systems, a dedicated sparkling water tank (for example, 1.8 L in several HoReCa configurations) helps stabilize sparkling output while the system cycles during heavy use.

Operational best practices that reduce carbonation complaints

- Use food-grade CO₂ and a properly rated regulator; train staff on cylinder changeover and leak checks.

- Prioritize stable cold performance; colder water generally holds carbonation better and tastes crisper.

- Place the cylinder and lines where they remain protected and serviceable (especially for undercounter installs).

- Include a sanitation plan for any parts in contact with water, particularly dispensing outlets and drip areas.

From a supplier standpoint, the highest-performing deployments are those where the CO₂ and water pathways are designed as a system: correct installation prevents downtime, and routine checks prevent “flat” pours that negatively affect perceived quality.

Maintenance and Hygiene: A Simple Plan That Protects Uptime

Commercial sparkling water dispensers succeed when maintenance is simple enough to execute consistently. Designs with easy-to-clean components and straightforward service access reduce the probability of taste drift, slow flow, and avoidable callbacks.

| Frequency | Task | Why it matters |

|---|---|---|

| Daily | Wipe external surfaces; clean drip tray and outlet area | Prevents visible hygiene issues and reduces microbial risk at touchpoints |

| Weekly | Inspect dispensing outlets; verify flow stability and carbonation “feel” | Early detection avoids peak-time failures and guest complaints |

| Monthly | Check CO₂ system (regulator, fittings, pressure stability); leak test if needed | Protects carbonation consistency and reduces gas waste |

| Per consumable schedule | Replace filters per water conditions and usage; sanitize internal pathways as required | Protects taste and safety and keeps the system operating at designed performance |

Common avoidable issues (and how to prevent them)

- Undersizing for peaks: select capacity for peak hour, not average day.

- Inaccessible installation: undercounter units must retain service clearance for filters and CO₂.

- Missed consumable changes: establish a replacement cadence and assign ownership (facility vs. outlet manager).

ROI and Sustainability: Quantify the Business Case with Simple Numbers

Commercial sparkling water dispensers are frequently justified on convenience and sustainability, but the decision becomes easier when you model a realistic scenario. Below is a straightforward example you can adapt to your operation.

Example: replace bottled sparkling water during peak season

Assume a venue currently sells or serves 150 bottles/day of sparkling water at 330 ml each. That is 49.5 L/day (150 × 0.33). Over 30 days, it becomes 1,485 L/month. A properly sized system with commercial output can cover this volume while reducing bottle storage, purchasing admin, and waste handling.

Where businesses typically see operational benefits

- Lower packaging logistics: fewer deliveries and less back-of-house storage pressure.

- Improved brand presentation: visible sustainability actions (reduced single-use bottles) often align with modern guest expectations.

- Energy-saving design options: many commercial dispensers are designed with energy-efficient components intended to reduce operating costs over time.

From a supplier viewpoint, the best long-term outcomes happen when specification, installation, and maintenance are treated as one project. If you want help mapping your peak demand, preferred water options (sparkling/cold/ambient/hot), and installation constraints to the most suitable configuration, you can coordinate specifications through our contact channel and we will recommend a fit-for-purpose commercial solution with clear consumables and service expectations.

Practical conclusion: A well-sized commercial sparkling water dispenser can materially reduce service friction while supporting sustainability goals—provided you size for peak demand, choose a serviceable layout, and follow a simple maintenance cadence.

Language

Language

English

English Español

Español

ADDRESS

ADDRESS CONTACT

CONTACT EMAIL

EMAIL